Process Introduction

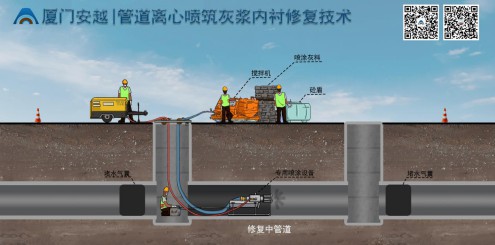

The technology principle of Shield repair technology for tiny pipes :

Deliver the pre-prepared paste lined slurry pump which is poured evenly to the inner wall of the pipe under the action of centrifugal force to the high-speed rotary nozzle driven by compressed air on the central axis of the pipeline.

At the same time, driven by the traction winch, the rotary nozzle slowly drags along the Central Line of the pipe, making the lining slurry form a continuous dense lining layer in the pipe wall.

When a turn is finished, the second and third layers can be sprayed until the lining reaches the designed thickness.

Material performance

High strength

Excellent workability

Abrasion resistance

Corrosion resistance

Uniform application

Densely compacted

Safe operation

Precise thickness

The material used for pipeline centrifugal spraying repair is a kind of mortar material based on modified cement and additives. The mortar material and a certain amount of water are sufficiently stirred to form a paste material suitable for spraying, pouring or pumping at least 6mm. The hardened liner tube is densely compacted, so as to ensure its excellent impermeability.

The performance is attributed to the scientific ratio of various components in the material, including organic additives, thickeners, rust inhibitors and other chemical admixture. Quartz sand plays an important role in shaping, improving fluidity and increasing density of hardened body. Beyond that, the composite has excellent slicing toughness, high elastic modulus and self-cementing properties. The addition of fiber materials makes the materials have stronger cohesion and flexural strength after hardening.

Project case