Uv-cipp local repair technology

Uv-cipp local repair technology is a kind of repair scheme that UV resin and epoxy resin are applied on glass cloth, the fiber cloth coated with resin is wrapped on the repair air bag, inflated to make it close to the main pipe and solidified.

Process introduction

The heat output of the UV lamp reacts with the exothermic reaction of the UV resin to ensure the optimal temperature of the second layer of cured epoxy resin, fast curing (UV resin), and ideal adhesion (epoxy resin).

During the application of uv-cipp local repair technology, the short liner pipe is wrapped on an expandable drum, pulled into the part to be repaired by winch, and then the drum is expanded by high-pressure gas to fit the old pipe tightly.

Process advantages

Curing cooling time 10 minutes;

The inner surface is smooth, which can improve the flow capacity of the pipeline;

Some water flow in the pipe can also be constructed, reducing the cost of pipe closure and sewage diversion;

Quiet and safe construction (no heating process or chemical reaction process during construction), no noise and no pollution to the surrounding environment

Scope of application

Renewal of gravity sewer

Applicable pipe diameter dn150-dn600mm

Length 0.5m ~ 1.0m

Process Brief

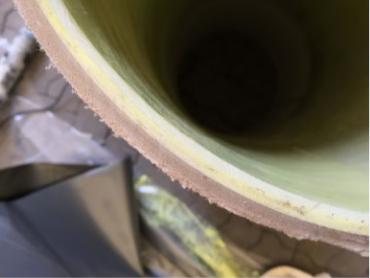

1. Cut fiberglass cloth as required

2. Glass fiber cloth impregnated with epoxy resin

3. Glass fiber cloth wound on the mender

4. Fix fiberglass cloth with special tape

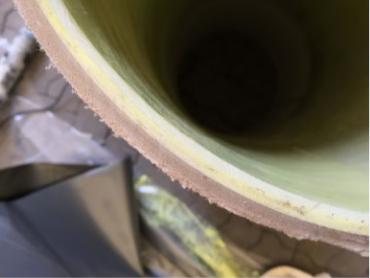

5. Turn on the UV light to cure the resin

5. Turn on the UV light to cure the resin