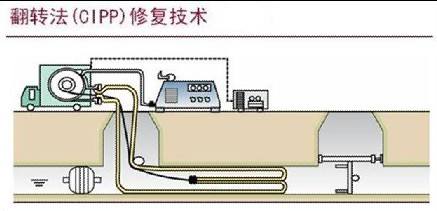

Process description

The most commonly used CIPP liners are for installation by the inversion method. Inversion is the process where the liner is turned inside-out during the installation using a column of water or pressurized air; the liner walks itself through the host pipe. Inversion results with the exterior liner coating becoming the new interior pipe wall surface with the resin saturated felt pressed against the host pipe wall. The inversion process can be done using air pressure (a shooter or air inverter) or a water column (inversion water column). Water inversion was the original installation method used for over 25 years before air inversion method was developed.

Technical advantages

The liner is made of polyester fiber felt (internal layer) and polyurethane (external layer). It is fully impregnated and installed into the host pipes.

Technical process

Insert auxiliary lining pipe

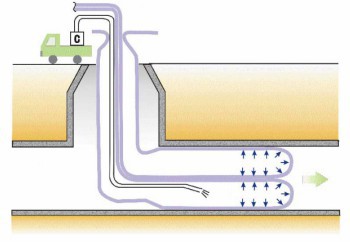

Flipping insert resin hose

Lining pipe formed by circulation of hot water/steam

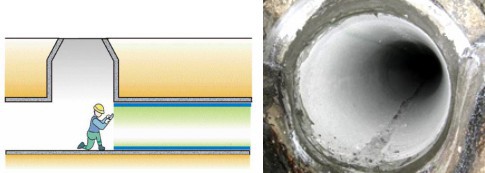

Waterproof treatment of pipe ends

Consequence Introduction

Before

After