1.Description

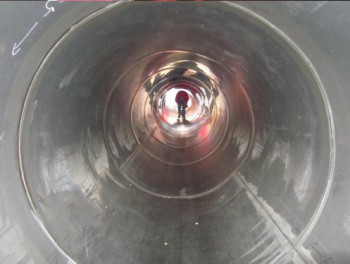

Stainless steel lining technology began to be used in the mid-1960s, which is to take thin-walled stainless steel tubes as carriers, weld them into shape, and then use the traction winch as the power to pull the stainless steel lined tubes from one end of the pipeline to the other end. After the interpenetration of the lining pipe of the stainless steel pipe, it is pressed, and the gap between the lining pipe and the original pipe is injected and solidified under the condition of maintaining pressure. Form with the original pipe tightly bonding, smooth surface of the composite pipe. So as to achieve the purpose of repairing with strong bearing capacity, impact resistance and overall corrosion resistance, and extend the service life of the original pipeline for more than 50 years.

2.Advantage

Stainless steel lined pipe adopt to compound stainless steel tube on the inner wall of outer backing pipe. This lined pipe is greatly improved in watersupply, sewage treatment, oil & nature gas transportation in the process of corrosion resistance, smooth surface, Small fluid resistance; and retain the high mechanical strength of steel pipe, pipeline was connected by welding, groove, thread connection, good sealing, it overcomes the easy corrosion to steel pipe, the defects of easy leakage and aging of plastic pipes with hot melt connection, It is an ideal product for the upgrading of gas, water and oil pipeline.

3.Filed of application

Oil &Gas transportation pipeline

Power Plant pipeline

Paper and Pulp industry

Pharmacy & Medical

Water supply pipeline

Food & Beverage pipeline

4.Specification

Material of liner pipe:304,316L,2205,Duplex Stainless Steel, Austenitic Stainless Steel

Outer Diameter(mm): 20~1420

Wall thickness(mm):Outer backing pipe 2.5~50;Liner steel pipe 0.2~6

Composite Standard:API-5LD;DNV-OS-F101;DEP 31.40.20.32; CJ/T192;

Packing: In bulk or according to customers’ requirements.

MOQ(Meters):100

The gripping force (σy) between the lining and the backing steel:

Thickness of the lining /mm | The gripping force (sy) /MPa | Remark |

≥3.0 | ≥150 |

|

2.0~3.0 | ≥90 |

|

1.0~2.0 | ≥60 |

|

<1.0 | —— | Untested |