Quick lock series

Product information | |

NO. | Size(D*L)/mm |

1 | 300*300 |

2 | 400*300 |

3 | 500*300 |

4 | 600*300 |

5 | 700*300 |

6 | 800*300 |

7 | 900*300 |

8 | 1000*300 |

9 | 1100*300 |

10 | 1200*300 |

11 | 1400*300 |

12 | 1500*300 |

Product Introduction of QuickLock -S and QuickLock -L

QuickLock-S®

Quickly solve local pipe defects

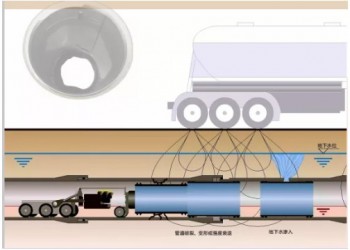

QuickLock is a strictly mechanical point repair system for the inside repair of pipes. No resin is involved. This revolutionary system consists of only (2) components: a 316L stainless steel sleeve structural body, covered by a seamless EPDM compression seal. Through the manhole the sleeve is inserted into the pipe and placed over the damaged section. Using an inflatable packer, the sleeve is then expanded and permanently locked into position.

1.Technical advantages

Trenchless no-dig spot repair

Permanent, reliable, and instant fix

Passes air & water pressure testing.

Reinstates structural strength & integrity of deformed and damaged pipe.

Can be installed with flow present.

Easy and quick installation - no cure time.

Applicable for internal pressure up to 220 psi*

2.Scope of application

For defects with a large length along the axial direction of the pipeline, several "quick locks-s" can be continuously overlapped and installed, which theoretically can be extended indefinitely. Applicable pipe diameter: DN150-DN700mm.

3.Consequence Introduction

QuickLock-L®

Solve the local defect problem of large diameter drainage pipe quickly.

QuickLock-L is a strictly mechanical point repair system for the inside repair of pipes. No resin is involved. This revolutionary system consists of only (2) components: a 316L stainless steel sleeve structural body, covered by a seamless EPDM compression seal. Through the manhole the sleeve is inserted into the pipe and placed over the damaged section. Using an inflatable packer, the sleeve is then expanded and permanently locked into position.

1.Technical advantages

Trenchless no-dig spot repair

Permanent, reliable, and instant fix

Passes air & water pressure testing.

Reinstates structural strength & integrity of deformed and damaged pipe.

Can be installed with flow present.

Easy and quick installation - no cure time.

Applicable for internal pressure up to 220 psi*

2.Scope of application

For defects with a large length along the axial direction of the pipeline, several "quick locks-x" continuous lap installation can be theoretically extended indefinitely.

Be suitable for the pipe diameter from 800mm to 1,800 mm.

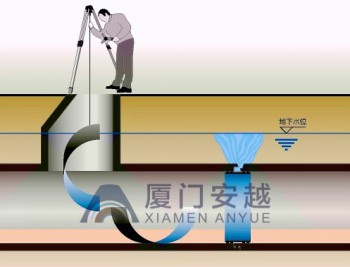

3.Installation Process

Determine if correct application for QuickLock.

Determine exact pipe ID.

Determine damage length.

Prepare the QuickLock sleeve.

Load the sleeve on the QuickLock Packer.

Deliver the QuickLock sleeve to the installation.

Inflate the Packer to install the sleeve.

4.Consequence Introduction

Before

After