Speedpac ® H100 is a kind of one component, hydrophobic polyurethane material. It reacts rapidly when encountering water and expands with foaming. It is mainly used for sealing cracks of structures, with obvious effect of water inrush.

1. React with water, foaming and expansion, the expansion amount can be up to 20 times in a short time, forming a closed waterproof system in cracks

2. The curing time (catalyst content) can be adjusted according to the needs of the project, and the effect is obvious under the water gushing environment

3. The water-proof body after reaction is resistant to acid, alkali, organic solvent and chemical corrosion

4. The compressive strength of waterproof consolidation body can reach 20MPa

1. Plugging of structure cracks

2. Inspection well wall plugging

3. Leakage and leakage stoppage of pipeline interface

4. The tunnel face is stable and the segment interface is waterproof

5. Sealing of construction joints of underground structures

6. Soil consolidation

Speedpac ® hf300 polyurethane water stop material

Speedpac ® hf300 is a one component, low viscosity, water reactive, closed cell polyurethane water stop resin. The material is solvent-free and o-phthalate-free. It is mainly used for water inrush treatment and cavity filling.

Material properties

1. the single component resin is easy to be constructed, and the foam after reaction with water fully occupies the existing pores and forms a good watertight effect.

2. Start reaction in 6 seconds at most, complete reaction in 30 seconds, and the maximum expansion in a short time can reach 50 times

3. The reaction rate can be controlled by controlling the amount of catalyst. When the backwater pressure of the water leakage structure is large and the injection flow rate of the material is low, the catalyst should be added to increase the foaming rate;

4. the polyurethane foam finished by reaction is brittle, showing good mechanical strength and chemical resistance.

5. The consolidated body is harmless to the environment and can resist all kinds of biodegradation.

Application scope

1. Fast water plugging under the condition of large flow or high pressure and large flow leakage and water gushing;

2. Sealing of foundation joints such as diaphragm wall and steel sheet pile;

3. Water plugging in large fissures, cavities or pebbles;

4. Advance grouting or post grouting for mine, tunnel, pipe jacking engineering, drilling and blasting construction, shield construction, etc;

5. Concrete crack and honeycomb grouting filling;

6. Water blocking of drainage facilities and filling of underground cavities;

7. Water plugging of various inspection wells.

Speedpac ® F400 elastic polyurethane water stop material

Spek F400 is a kind of one component flexible polyurethane resin water stop material, which is hydrophobic, self foaming and elastic, and is suitable for water stop of expansion joints, sealing of displacement cracks and water blocking of concrete or masonry structures. When contacted with water, the material will react quickly and rapidly expand and expand. The elastic foam formed can achieve permanent sealing effect.

Material properties

>Reaction with water, foaming and expansion, good elongation at break, effective elastic water stop

>Elastic seal can be formed in a very short time

>After reaction, the solidified body is resistant to acid, alkali and organic solvent, and has good chemical corrosion resistance

>Through WQA international drinking water certification, it can be used in water supply pump station, water supply pipeline, etc

Application scope

>Plugging of tunnels and subways

>Plugging of basement

>Repair of inspection well leakage

>Dam leakage and water stop

>Sewage pipe and pump station

>Steel sheet pile plugging

Speedpac ® GT350 elastic polyurethane water stop material

Low viscosity, flexible and hydrophilic grouting resin for crack and joint grouting

Quick Parker GT350 is a MDI based single component hydrophilic and low viscosity polyurethane grouting material. When the material is injected into the fissure or pore, it will react with water rapidly and expand and expand. The elastic foam formed by the material can achieve permanent water stop effect, and is used for sealing cracks, pores and expansion joints of various structures.

Material characteristics

1. the single component resin is easy to be constructed, and the foam after reaction with water fully occupies the existing pores and forms a good watertight effect.

2. The viscosity of resin increases rapidly with the occurrence of in-situ reaction, and the reaction speed can also be accelerated by catalyst;

3. It can be used for single component injection or mixed with water less than 2 times of its volume;

4. Foaming ratio 4.5-7 times;

The foam formed by the 5. has good flexibility and is very suitable for sealing water at expansion joints and settlement joints.

6. the foams formed are environmentally benign and can resist various biodegradation.

Application scope

1. Sealing of cracks caused by deformation and settlement of drainage facilities of brick concrete structure;

2. Sealing of foundation joints such as diaphragm wall and steel sheet pile;

3. Water sealing of overlapping joints of tunnel segments;

4. Grouting of outer wall of pipe and tunnel segment;

5. Replacement grouting of the failed aquiclude.

Storage and shelf life

1. Speedpac resin is very sensitive to moisture, and should be stored in a dry environment of 5 ℃ ~ 30 ℃.

2. The storage period of resin materials in unsealed state is 24 months.

3. The storage period of resin catalyst in unsealed state is 24 months.

4. Once unsealed, it shall be used up in the shortest time.

Safety tips

To avoid materials entering eyes or directly contacting with skin, appropriate labor protection shall be taken in combination with local laws and regulations; read the material safety data sheet carefully.

Speedpac epoxy spray material

Material characteristics

Type and performance of epoxy resin:

This product is suitable for repairing and protecting concrete.

It is a simple mixed spray epoxy coating.

·For wet and dry surfaces

·High adhesion

·Simple mixing ratio and color control

·Hard durable coating

·Completely watertight

·Easy to overlap; new coating will cover perfectly and stick to existing coating

·Full thickness in 1 workflow (1-3mm)

·Good adhesion to concrete, brick, steel and wood surfaces.

Red group A and gray group B materials

Process introduction

The epoxy resin spraying method is a pipe repair method which uses a high-pressure air compressor to spray resin slurry to the inner wall of the pipe to form the pipe lining.

Scope of application

·Plugging and strengthening of tunnels, subways and utility tunnels

·Leakage repair of pipes and culverts

·Foundation pit and anchor cable sealing

·Water treatment plant

·Sewage treatment

·Shaft and inspection pit

·Tanks and surge tanks

Pressure station

Inspection wells

Effect display

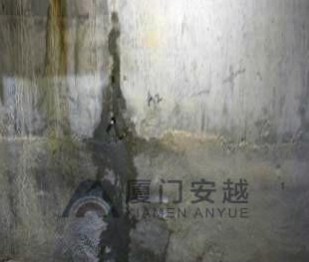

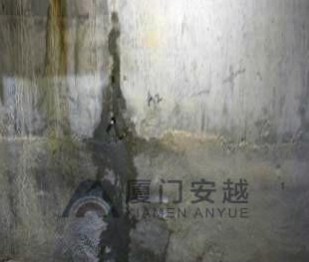

Picture before repair

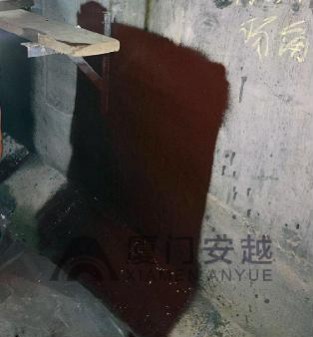

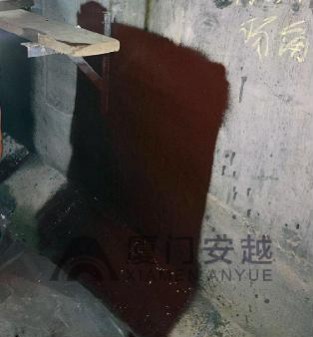

Picture after repair