Product introduction

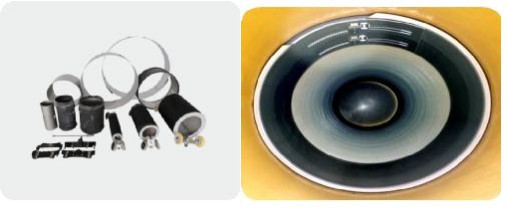

Stainless steel quick lock is composed of high-quality stainless steel ferrule, special locking mechanism and EPDM rubber ring. Compared with other local repair processes, it can be used for local repair of drainage pipes of any material and water supply pipes of a certain pressure, with the characteristics of no curing, no foaming, simple operation, reliable and efficient. According to different applicable pipe diameters, it can be divided into small diameter quick lock-s ® for dn150-800 and large diameter quick lock-l ® for 800-1800.

Process characteristics:

1. The whole repair process is fast, safe and reliable! No need for excavation and repair;

2. The construction time is short, and the installation, positioning and repair can be completed within one hour generally;

3. The repaired pipe wall is smooth, which can improve the water flow capacity;

4. It can carry water for operation and is easy to operate;

5. It can be used continuously and widely;

6. Stainless steel is acid and alkali resistant, and EPDM has strong water tightness;

7. The equipment used is small in size, easy to install and transfer, just one minibus;

8. There is no heating process or chemical reaction process in the construction, and there is no pollution and damage to the surrounding environment.

Scope of application

1. Unsealed section of old pipeline and unsealed section of joint interface

2. Local damage of pipe wall

3. Circumferential and local longitudinal cracks

4. Block the branch line interface that is no longer needed

Quick lock - s ®

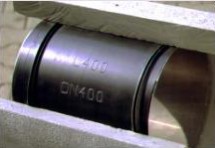

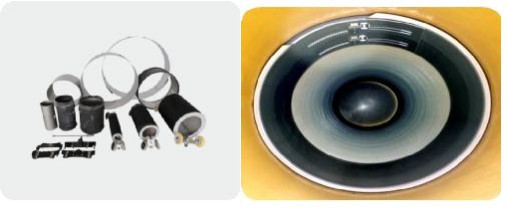

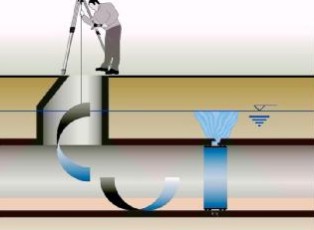

The special quick lock-s ® system for local repair of small pipes is composed of high-quality stainless steel ferrule, special locking mechanism and EPDM rubber ring formed by stamping. During pipeline repair construction, with the help of pipeline robot, the special repair airbag carrying "quick lock-s ®" is positioned at the position to be repaired, and then inflated to expand the airbag, and then the quick lock is opened and tightly pressed against the pipe Then take out the air bag to relieve the pressure and complete the pipeline repair.

Quick lock - s ® installation technology

1. CCTV detection robot

2. Quick lock positioning expansion equipment (repair airbag)

3. Vent pipe: connect CCTV and expansion equipment

4. On board air compressor: at least 5.0bar output pressure

5. Air hose: at least 100m

工程案例

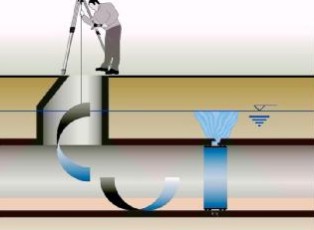

Quick lock - L ®

Quick lock - L ® for local repair of large diameter pipeline is composed of high-quality stainless steel ring slice, special locking bolt and EPDM rubber ring. During the pipeline repair construction, workers enter the pipeline to be repaired, first assemble the stainless steel ring piece into a ferrule slightly smaller than the inner diameter of the pipeline, and then put the EPDM rubber ring on the outside of the ferrule, and then correctly place the ferrule on the part to be repaired and use the special installation tools to open and tension the quick locking ring, so that the ferrule and rubber ring are closely and seamlessly connected with the pipe wall, and then lock the special locking bolt Complete the local repair of the pipeline.

Engineering case

UV curing bottom film

Bottom film: perfect protection of UV curing hose during pulling in

Material characteristics

The bottom film plays an important role in the process of hose installation, because even if the obstacles are removed in advance by robot technology, there will be some sharp edges and corners. These corners can cause saponification and leakage, so it is very important to avoid these corners.

Therefore, the bottom film is inserted before the UV curing hose is inserted into the aging pipeline, so as to prevent damage and ensure the quality of repair works. The size of the hose and the bottom film is designed to extend slightly during installation to ensure an absolutely smooth surface.

The bottom film has a very low friction coefficient, which can reduce the amount of work needed to insert the hose. In order to further reduce the insertion force, we will also use lubricants.